Optimising your gas for lower bills with Optergas

Supplied & installed for a one off fee of only £350

Saving you up to £250 per year - year on year!

Use our savings calculator to work out how much Optergas can save on your bills annually.

What Is Optergas?

Optergas is an easy to install fuel saving system, offering a proven reduction in oil or gas consumption. Read More >

What Is Optergas?

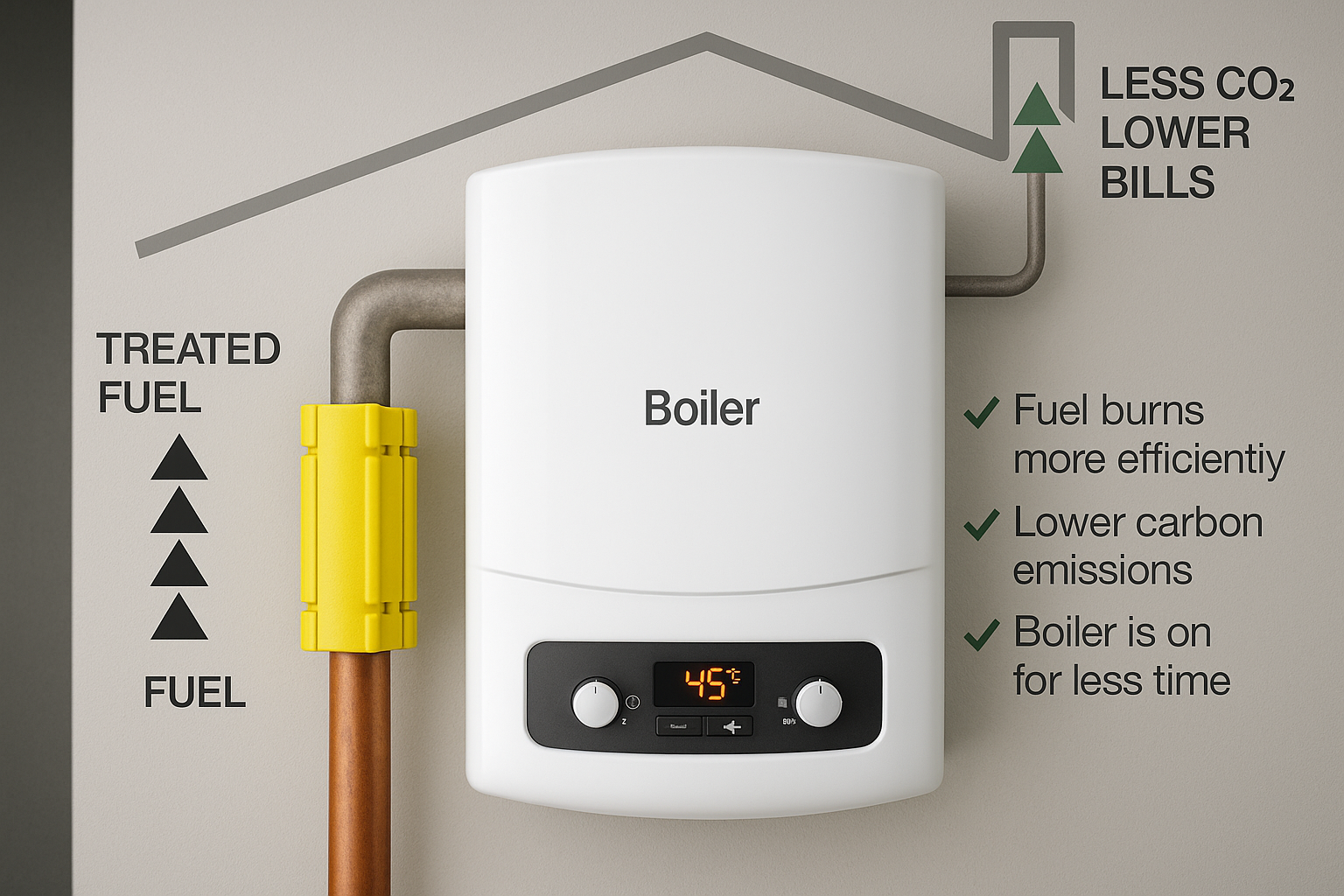

Optergas simply boosts your boilers fuel efficiency by up to 20%.

What Is Optergas?

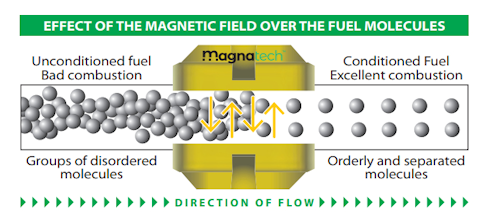

Optergas utilises advanced technology based on the discovery that strategically placed high-powered magnets on fuel feed pipes enhance combustion efficiency. This process increases the flame temperature by up to 120°C—well within the boiler’s tolerance—optimizing overall performance.

The stability of Optergas units ensures improved boiler efficiency across various configurations and flow rates, resulting in significant cost savings and increased profitability.

The Technology.

The Optergas system has been extensively researched by Magnatech™ and has been tested, and designed to maximize energy efficiency.

The development of the Optergas unit and its installation process has taken over a decade of rigorous research and testing by Magnatech™. Their products are engineered to exact specifications, utilising the most powerful Neodymium magnets available today.

This proprietary approach to harnessing advanced magnetic technology and optimising combustion behaviour is what makes the Optergas unit so effective in delivering long-lasting energy savings.

Why Optergas?

Optergas helps to preserve fuel supplies and provide CONSIDERABLE SAVINGS to all home energy consumers.

Rising Prices

Between 1st October to 31st December 2024 the energy price cap was set at £1,717 per year for a typical household who use electricity and gas and pay by Direct Debit. This is an increase of 10% compared to the cap set between 1 July to 30 September 2024 (£1,568).

Why Optergas?

By installing an Optergas energy-saving device, you can reduce your energy bills by up to 20% thanks to its revolutionary technology.

Easily fitted to your existing pipework, this innovative solution helps you achieve long-term savings year after year.

Our Partners & Case Studies:

Energy Saving Solutions For Every Need

INNOVATION

Optergas™ started developing energy saving products and refining Optergas™ Technology 14 years ago, using "probably" the world's most powerful, double nickel coated Neodymium magnets to "condition" fuel.

ENERGY SAVING

The Optergas Energy Saving System is suitable for oil, gas and LPG powered boilers and water heaters, it's easy to install, requires no downtime and is proven to save up to 15% on your bills, every year for life!

THE TECHNOLOGY

Polarisation of the hydrocarbon molecules creates a more combustible material resulting in a brighter and hotter flame. The increase is to approximately 120ºC.

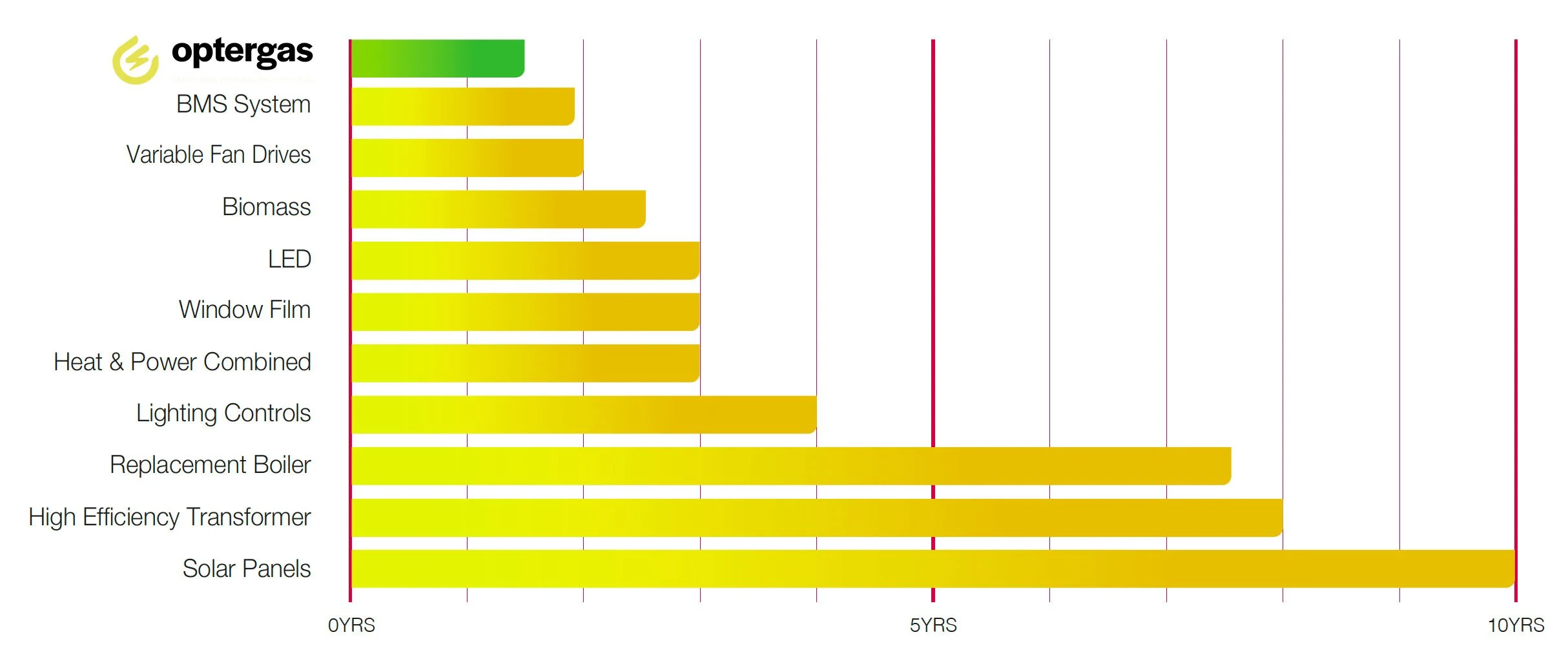

Return on Investment

Payback time comparison for energy saving technologies

Estimate Your Optergas Savings

Supplied & installed for just £350 – pays for itself in as little as 2 years!

Saving you up to £250 per year - year on year!

Savings Reports

Proud Partners With BeSure

We’re proud to partner with national boiler installers BeSure Group

BeSure Group, a name you can trust

BeSure is our top choice for installing all Optergas Smart Devices. With a nationwide reach and a network of Gas Safe installers, BeSure is ideally suited to install your Optergas Smart Device.

Looking for a new boiler?

BeSure also installs boilers throughout the county. If you need a new boiler, with a 15-year warranty, request a quote today and discover how much you can save with a new A-rated boiler and an Optergas Smart Device.

What Our Customers Are Saying

Sustainable Future With Optergas

Magnatech device installed by Optergas has been independently verified by the Environmental Technologies Verification Scheme (Tritech ETV) and is guaranteed to reduce fuel consumption in the home. The device works by using proven magnetic technology to raise the temperature at which your boiler burns fuel, which in turn makes it burn more efficiently with less wastage. This allows your home to reach the desired temperature more quickly, so your boiler is on for less time. You burn less fuel, and cut your heating bills and carbon footprint all in one easy step.

Frequently Asked Questions

-

The fuel flows through a series of alternating poles and the positive and negative parts of the hydrocarbon molecule are affected by these alternating poles, they will try to stabilise and will do so after a short time but if they are moved into an area with oxygen then they will bond with that oxygen and make a more combustible material, causing all of the fuel to burn at once and so making a shorter brighter and hotter flame. There are other theories on the process but it is accepted that there is a temperature increase. The increase is about 120C.

-

The simple response is that the customer will know how much fuel they use and when they have changes in production that might make a difference to consumption. If customers need help with the calculations and how to compare a mild month with a cold month then Optergas can help with that. Basically, there needs to be a good quality base line to measure the results from, at least, 3 months of data. The magnets are put on the fuel line and then after 6 weeks the data is collected again for another 6 weeks (the reason for the 6 week gap is to allow the magnetic field to go into the pipework) the results for the last 6 weeks are then compared to the base line (using degree days if necessary) and there should be a reduction, if the customer would like longer to monitor the data then this can be agreed.

-

No, Optergas does nothing to affect the boiler and we do not touch it at all. When boiler manufacturers have been contacted they have said that so long as the magnetic fields do not affect their sensitive valves or switches then they have no problem with the installation. Almost all sensitive parts of a boiler are encased in an alloy material; this material does not carry magnetic fields. The magnets do not affect any sensitive devices unless they are actually placed on the magnets, which is impossible. The temperature increase in the flame is well within the tolerances of any boiler and it is a small percentage increase. We have installed our units on tens of thousands of boilers dating back over 14 years and we have never had any problems reported to us.

-

The results can be influenced by a variety of things, the outside temperature is a major one, the temperature of incoming water for steam boilers, and for heating systems even the wind and the speed of heat loss can make a difference. Variations in production and demand, alterations to the raw material, new processes being introduced, new leakage and heating loss. The variation of calorific value of fuels supplied by a fuel company. But most significantly of all are people. Systems where there is no unauthorised interference and where there are very accurate thermostats are the best ones. Size is a factor, particularly pipe size and material, as the penetration into the pipe is less as the pipe size increases and if all the pipework is too big then the Optergas units cannot be installed.

-

Pressure in itself does not make a difference but speed of flow does. If the system has a high speed such as on CHP (Combined Heat and Power) then it is unlikely that enough magnets can be placed close enough to the point of combustion to make a difference. Again pipe size and use of the boiler could influence the number of units required. If there is just a fan on the gas line to speed up flow then that should not be a problem.

-

Not by standing close to the magnets. The magnets are constructed so the backs (facing away from the pipe) do not lose very much magnetic power. You have to be touching the units or be putting them on the pipe work to be affected - the only affects are that your fingers may be trapped under the magnets and between the pipes.

-

Certificates such as CE mark are not required for this type of product but we do have independent verification from the TRITECH ETV project, an EU funded project to help identify new technologies that are good for the environment and to help speed them into the market place. This allows potential clients to buy with confidence knowing that they have been independently verified to meet the manufacturers claims. In Magnatech's case a saving of over 10% were recorded.

-

They should be! Over the years the technology has slowly developed and adapted the range of magnets as lessons have been learnt and the demands of different installations met. This has enabled more and more companies to use them. Growth has been very quick in recent years as existing clients spread the word.

-

The average saving is 12% and we guarantee a minimum saving of 6%. Payback is usually within 1-2 years or earlier, making this the fastest Return on Investment system of its type in the market today.

Start Your Optergas Journey Today

Take the first step towards saving energy on your bills. Enquire today to get your Optergas device installed and start saving now.

How we ensure delivery of Optergas energy saving promise.

When people invest in energy efficiency, whether in a domestic or industrial setting, they will want to know how much they are saving and how long those savings will last. To ensure the credibility and consistency of energy-saving claims, accurate measurement and a replicable methodology are essential. We achieve this through the Magnatech use of a measurement and verification (M&V) protocol.

Complete the form to request a document showcasing the testing protocol. It explains the steps and procedures involved to ensure that we can deliver the level of energy savings that we promise, making sure that our customers can have the same level of confidence in our product that we do.